DAS SAGEN UNSERE KUNDEN

Kunden-Testimonial: Über uns

Die Zusammenarbeit mit Westo hat den großen Vorteil, dass es sich um ein großes Netzwerk aus Fachleuten handelt. So lassen sich mehrere Bedürfnisse in einem Prozess vereinen. Die Kommunikationswege sind effizienter und das Ergebnis eins A.

Test2

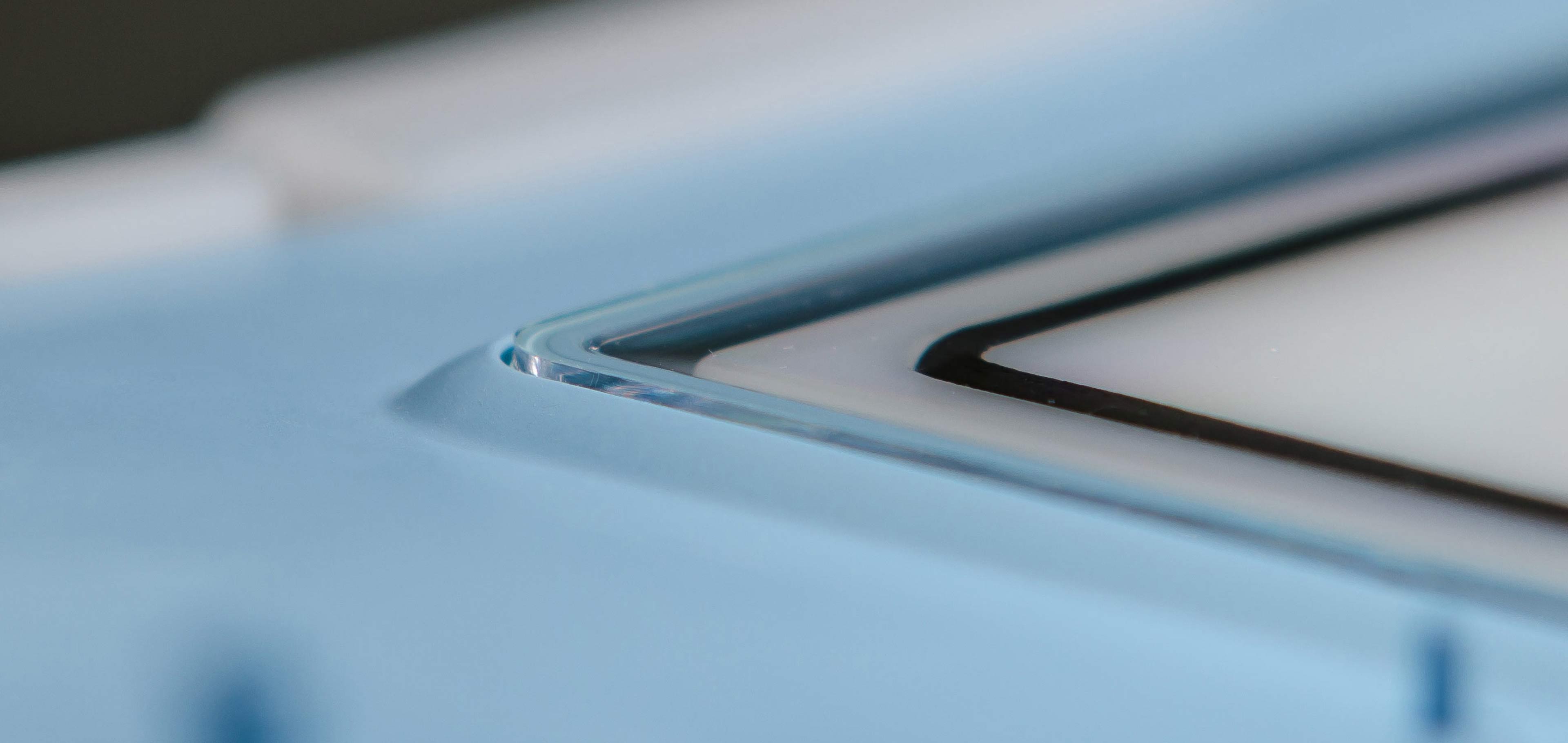

Man merkt, dass sich Westo auf die Verarbeitung von Kunststoff spezialisiert hat. Die Beratung ist zuverlässig, die Möglichkeiten vielfältig und das Ergebnis mehr als zufriedenstellend.

Test

Man merkt, dass sich Westo auf die Verarbeitung von Kunststoff spezialisiert hat. Die Beratung ist zuverlässig, die Möglichkeiten vielfältig und das Ergebnis mehr als zufriedenstellend.